Fakuma Preview: Manufacturing cell made by Haitian brings cost-effectiveness to the point

2023-10-12

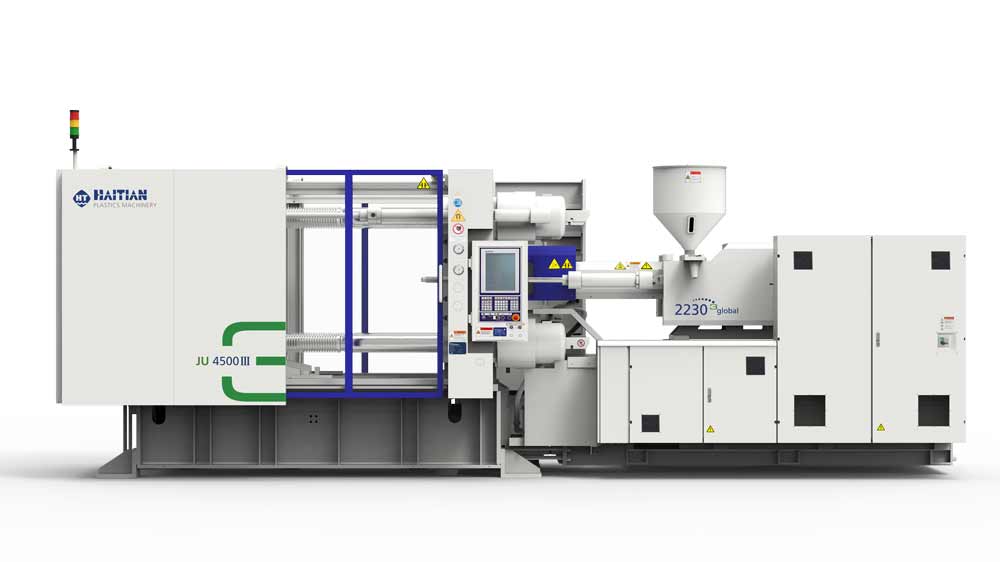

The compact two-platen technology of the Haitian Jupiter series, with clamping forces between 4,500 kN and 88,000 kN, has firmly established itself in the market. Haitian International Germany already has more than 350 two-platen machines in the field in Germany alone and more than 1200 in Europe. More than 100 of these are in the range greater than 10,000 kN.

The main areas of application are the automotive industry, logistics, the commodity sector and the construction industry. In line with the product strategy “Technology to the Point”, the Jupiter series scores not only with the general advantages of the two-platen technology, but also with a tailor-made servo-hydraulic system developed in-house for high performance, high precision and low energy consumption.

Haitian Jupiter Series live at Fakuma: Presentation of a manufacturing cell made by Haitian

Application data at a glance:

- Shot weight 448 g

- Cycle time 50 s

- 4+4 cavities

- Energy consumption machine ~0,31 kWh/kg

Linear robots made by Hilectro provide efficient solutions for reliable part removal from injection molding machines with clamping forces ranging from 600 to 40,000 kN and loads up to 80 kg. They are manufactured within the Haitian Group.

Other Haitian and Zhafir manufacturing cells with Hilectro Robots can be seen at ONI-Wärmetrafo GmbH (Hall A5, 5103) and Gollmer Formen GmbH (Hall A2, 2213).

About Haitian International Germany

Haitian International Germany is a subsidiary of Haitian International Holding, one of the leading companies in the development and manufacturing of injection molding machines. Based in Ebermannsdorf, Bavaria, Germany, nearly 100 employees, plus another 70 employees in German agencies and over 200 sales and service technicians throughout Europe, guarantee reliable and fast order processing. In line with the principle of “technology to the point”, Haitian and Zhafir machines from 400 to 33,000 kN are assembled on 12,000 square meters of production space and equipped according to customer specifications right up to the finished automation cell: servo-hydraulic solutions with toggle lever or two-platen technology as well as electric and hybrid solutions. The extensive range of services includes a large pool of stock machines, spare parts, regular and free customer trainings, application tests and a comprehensive service network.