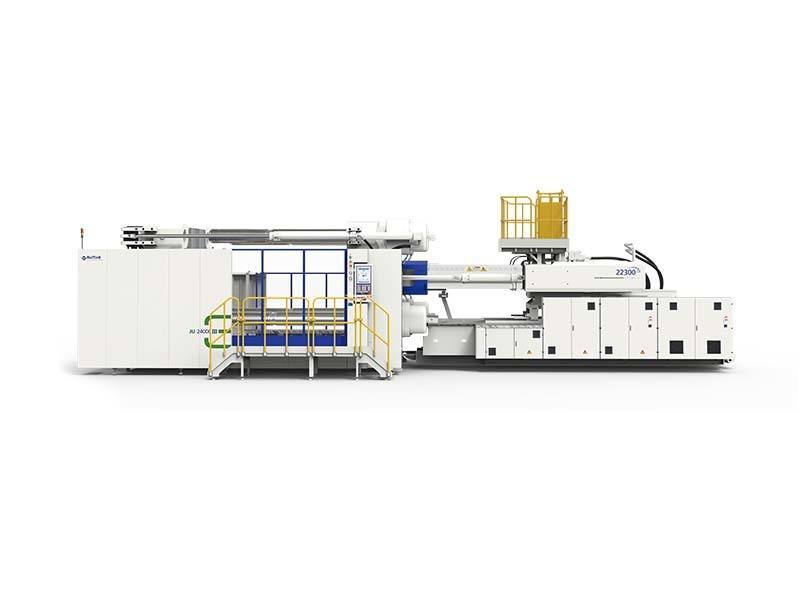

Compact two-platen solution with even more free space and open integration platform for intelligent control and digitization of processes – The new Jupiter III Series is now available in Europe up to 66.000 kN

The new Jupiter III Series is now available in Europe. At the 180,000 m² Haitian plant in Ningbo, China, about 650 employees are currently working on the production of the new JU series.

As a product with “Technology to the Point”, the further development of the JU Series focused on flexibility, simplification and ease of control in the application.

The footprint of the already space-saving two-platen machine has been further reduced, while the opening stroke and dimensions of the mold cavity have been increased.

Important for large-format products such as refuse containers, logistics pallets, white goods or long visible parts in the automotive sector. Tool changes are now also easier and maintenance work can be carried out more quickly.

Advances in production technology due to design innovations have led to more stable platen movements and shorter dry cycle times.

Highlights

News & Optimizations of the Jupiter III Series

New drive generation:

- 30% more speed and faster response times

- New, highly dynamic drive unit: higher torque, higher efficiency, less space

- GreenVantage: energy-saving, fine-stage drive unit with lower energy consumption and reduced noise level

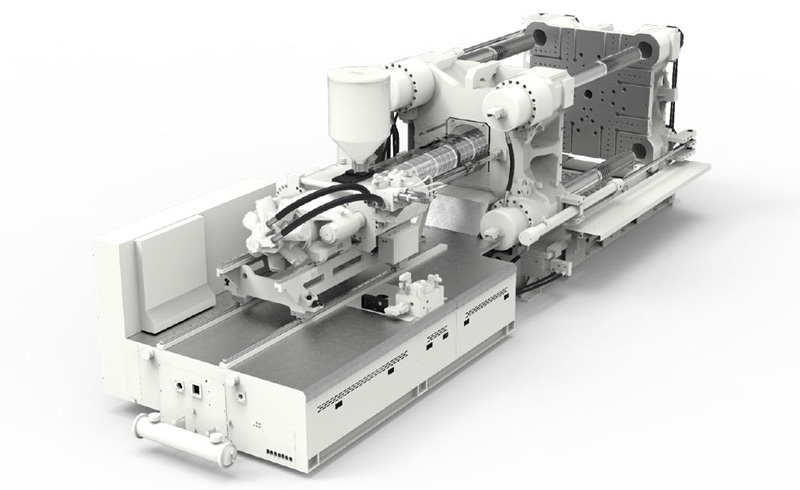

Reliable clamping unit:

- Compact design: more space for large molds, more free space inproduction and extended stroke for mold movement and ejector asoption

- New: Four independent short-stroke locking cylinders: precise mold height adjustment, balanced force of every tie bar. The mold remains closed during parallel movement

- Parallel locking system: fast, precise response and quiet

- Close movements: more precise and faster; shorter cycle times, quiet operation

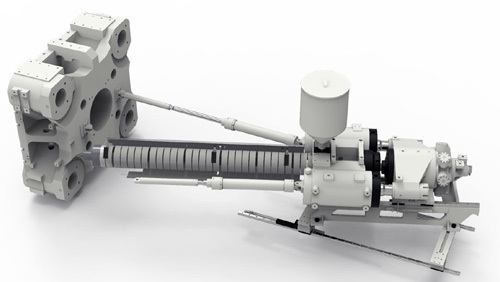

Precise injection unit:

- Linear guides for the main linear movements: lower friction and lower energy consumption, higher precision

- Free choice between multiple injection functions for greater injection performance and extended application range of the process

- Swiveling injection unit: faster screw and barrel change, easier maintenance